Top gearbox cvt Secrets

Top gearbox cvt Secrets

Blog Article

The 1965 Wheel Horse 875 and 1075 backyard garden tractors ended up the initial these kinds of autos to be equipped having a hydrostatic CVT. The look employed a variable-displacement swash-plate pump and stuck-displacement equipment-type hydraulic motor combined into an individual compact deal. Reverse ratios ended up reached by reversing the movement of the pump by way of around-centering with the swashplate.

Clogged transmission filter: The filter is chargeable for eliminating the contamination with the transmission fluid. When the filter is clogged or dirty, it will make your vehicle shake.

Easy Driving Working experience: With regards to the automobile and the motive force, a CVT can offer a smoother driving expertise in comparison to a conventional computerized.

Indeed, a CVT transmission might be repaired. Even so, it is important to note that repairs could be much more difficult than with conventional transmissions. It's also crucial to have an experienced mechanic that's experienced in dealing with CVT transmissions conduct any repairs.

Among the list of key drawbacks of CVTs is they can occasionally sense unresponsive or sluggish when accelerating from a end. This is due to the transmission normally takes time to regulate the pulleys and belt to the correct ratio to the motor’s energy output.

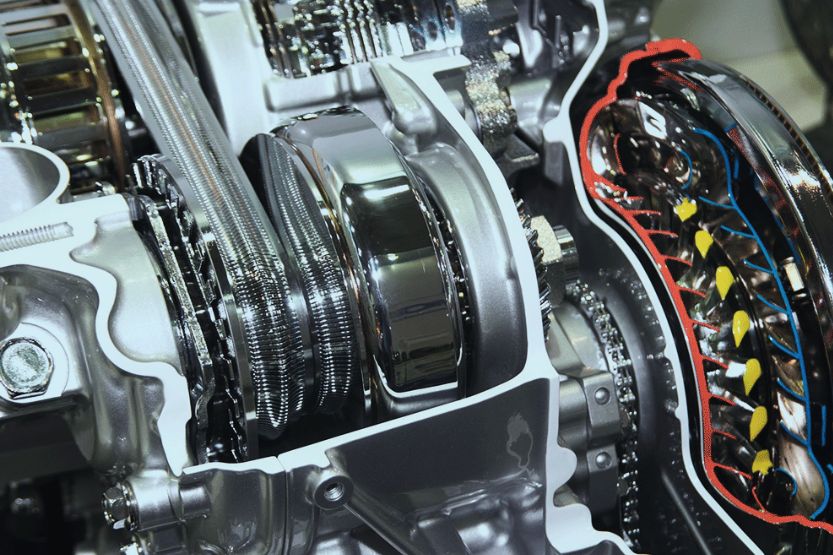

Most important and Secondary Pulleys: These pulleys are conical in shape and so are related by a belt or chain. The primary pulley is connected to the engine, plus the secondary pulley is linked to the wheels. The size on the pulleys changes continually to regulate the gear ratio.

In Cvt pulleys Engage in a very important role because the conical form pulleys integrated above input and output shafts are The key reason why for consistently variable transmission’s ongoing n-variety of pace and kit ratios, due to the various cross part of such conical pulleys numerous torque and pace ratios are attained.

The belt or chain is consistently transferring, and its stress is controlled via the Regulate program. The belt or chain’s rigidity is modified to maintain the proper gear ratio for the driving ailments.

The CVT has a great track record for reliability thanks to its simple design. What’s more, they sometimes guide somewhat unstressed lives simply because they’re mated to minimal-electrical power engines, like the kinds in superminis and hybrids.

As an example, when the pitch radius is little on the driving pulley and enormous on the driven pulley, then the rotational pace with the pushed pulley decreases, resulting in a decrease “equipment.” In the event the pitch radius is big on the driving pulley and little about the pushed pulley, then the rotational velocity of your driven pulley raises, leading to the next “equipment.” So, in concept, a CVT has an infinite number of "gears" that it could run as a result of at any time, at any engine or car pace.

Maintenance fees are frequently reduced for eCVTs as a consequence of fewer mechanical areas, though this may vary depending upon the complexity of the method.

Friction-disk transmissions were being used in many motor vehicles and little locomotives inbuilt the early twentieth century, such as the Lambert and Metz automobiles. Employed nowadays in snow blowers, these transmissions include an output disk that may be moved across the surface area in the enter disk upon which it rolls. In the event the read here output disk is modified to the position equal to its own radius, the ensuing travel ratio is one:one.

The CVT is made of various factors that get the job done alongside one another to deliver the continuous range of gear ratios. These parts involve:

As the gap involving the pulleys and the length in the belt isn't going to transform, both pulleys should be adjusted (one particular even larger, one other lesser) at the same time to take care of the right number of pressure about the belt. Uncomplicated CVTs combining a centrifugal push pulley by using a spring-loaded driven pulley usually use belt stress to effect the conforming changes during the pushed pulley.